Widely used in the water purification field, also has excellent chemical compatibility, suitable for acid, alkali and organic solvent filtration.

5/10/20 Inch 1/2/3/5/10/20/50 Micron Water Filter Cartridges

General description

The PP melt-blown filter cartridge is one kind of sediment filtration media, made by food grade Polypropylene material. It is produced by advanced gradient melt-blown technology. The material is melted in high temperatures and blown out by high-pressure air from the nozzle, becoming microfibers; then collected and shaped by a special receiving device.

Fiber diameter and tightness (Removal rating and density) are determined by rolling speed, collecting distance, air pressure, and feeding qty. The micron fiber will stick together without any glue before solidification. It will come into a “tight inside core and loose outside part” structure, that is to say, the filtration rating is in graded distribution from the inner to the outer part. This multi-layer deep filtration media can reduce flow resistance, increase flow rate, and collect contaminants inside different layers of fiber. It can do both rough and meticulous filtration, which works at both the surface and inside. Different-sized contaminants are held at different layers, which makes it have a big filtration capacity and long servicing life.

Contributed by the uniform and strong structure, shock-proof and anti-fatigue features, and chemical stability of Polypropylene material, the PP melt-blown filter cartridge is one of the best-qualified filtration media, widely used in petrifaction, chemical, auto, electronics, food, beverage, pharmacy, and medical industries. Economical price and stable filtration capacity are also advantages of PP filter.

Features and benefits

- Meets FDA requirements for food and beverage contact

- All construction without adhesives, binders, resins, or silicone, no media migration

- Gradual changing deep filtration structure with loose outside and close inner

- High dirt-holding capacity and flow rate in the low-pressure drop

- Excellent chemical properties of acid and alkali resistance

- High removal efficiency

- Lower cost and long service life

- Good compression and impact resistance

- Wide range of lengths and micron ratings

Application

- Reverse osmosis pre-filtration

- Food and beverages

- Acid and alkaline

- Machine oil and cutting oil

- Electronics

- Industrial water treatment

- DI water and ultra-pure water pre-filtration

- Plating and coating

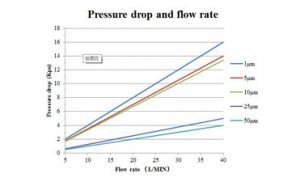

Flow rate & pressure drop

Production range

| Part | Item | Description |

| Specification | Materials | Polypropylene |

| Length | 5”,9.75″,9.87″,10”,20”,30”, 40”, 50”, 60”,70.” | |

| ID | Ф20 mm, Ф25 mm, Ф28 mm, Ф 38mm

(More cartridge size for option ) |

|

| OD | Ф15-300 mm | |

| Removal rating | 1,3,5,10,20,25,30,40,50,75,100,150μm | |

| Weight | 30~900 g (Adjustable) | |

| Adaptor | DOE, Flat, Fin etc. | |

| Surface | Smoothing type, Grooving type, Graining roll type, Keyhole and Logo on the surface. | |

| Performance | Operating temperature | 60℃(140℉) |

| Maximum differential pressure | 2.0 Bar, 21℃ | |

| Other | Packing | Shrink-wrapped individually or up to the customer’s request |

The professional manufacturer focuses on special melt-blown filter cartridge production, integrating with R&D, manufacturing, sales, and customer service.

The professional manufacturer focuses on special melt-blown filter cartridge production, integrating with R&D, manufacturing, sales, and customer service.